Planetary Gear Reducer

CATEGORIES

Send Message

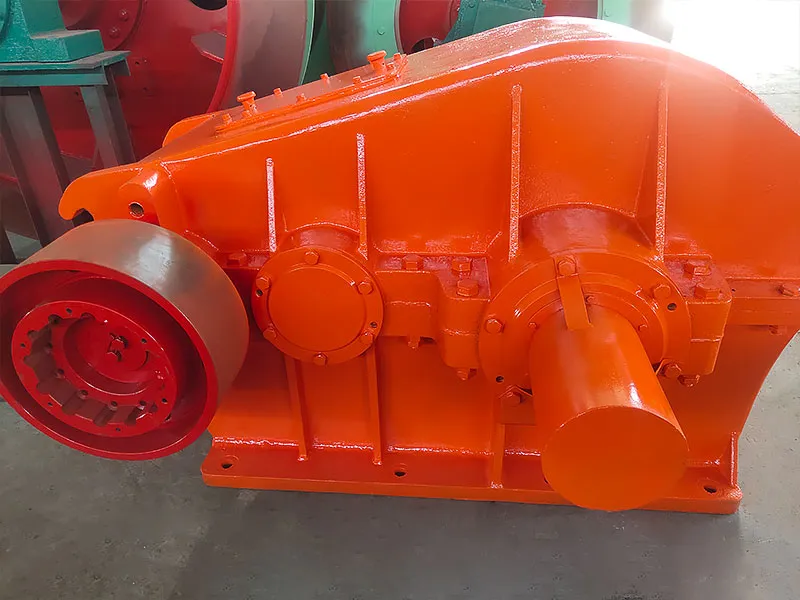

Product: Planetary Gear Reducer

Performance

By an internal gear ring is tightly combined to the shell of the tooth box, the ring gear center has a solar gear driven by the external power, between a group of three gears are equally combined in the planetary gear group on the tray, the planetary gear supports the output shaft, the internal gear and the solar gear support the output shaft connected to the tray to output power.

The inner gear of planetary reducer adopts 20CrMnTi carburizing quenching and grinding gear has the characteristics of small volume, light weight, high carrying capacity, long service life, stable operation, low noise, high output torque, large speed ratio, high efficiency and safe performance. With the characteristics of power diversion and multi-tooth engagement alone, important parts such as low speed gear, high speed gear and transmission shaft using low quality, medium carbon alloy materials such as: 18Cr2ni4WA, 42 CrMo, 40 Cr, etc., tooth surface hardness HRC 58-64. planetary gear reducer light weight, small volume, large transmission ratio range, high efficiency, stable operation, low noise and strong adaptability.

Technical feature

Planetary reducer of planetary reducer is different from the general way of traditional gear movement, traditional gear only by contact between size gear drive, all load on the contact, is easier to produce gear friction in fracture, in high speed than more need to have more gear connection, in addition to take up a lot of space, at the same time produce more friction loss, the gap of each reduction gear multiple accumulation, so its efficiency is low. When the planetary gear reducer is driven, there are six contact surfaces between the solar teeth, planetary teeth and inner ring teeth, and the inner tooth trajectory is 360 degrees, which can reduce the friction of the gear and make the gear have no danger of fracture. Planetary gear mining floating type motion, during the gap is quite close, each deceleration room only needs to be connected by the stage teeth, so its volume is relatively reduced, the highest efficiency can reach 97%.

CASE

Quality wins the market Trust creates the brand