JKMD Series Multi Rope Friction Hoist

CATEGORIES

Send Message

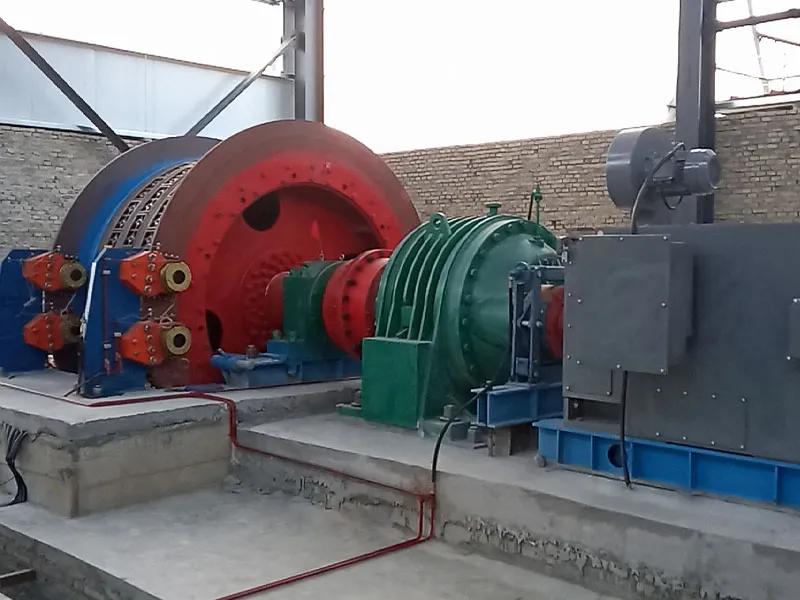

Product: JKMD Series Multi Rope Friction Hoist

Overview of the multi-rope friction hoist

The multi-rope friction elevator is mainly composed of motor, reducer, friction wheel, brake system, depth indicator, speed limit system and control system, driven by AC or DC motor. When using the low-speed motor without the reducer, the motor is directly connected with the coil spindle, or the motor rotor can be installed at the end of the coil spindle. When the transmission power is large, 2 or 4 electric motors can be used to drive at the same time. The total power of a elevator has reached 11,600 kilowatts. Brake system is an important device to ensure the safe operation of the hoist. In case of emergency, the braking system should produce two-stage safety braking through the hydraulic system that can adjust the brake torque to ensure that the elevator stops in time without producing excessive braking phenomenon. An AC motor-driven elevator. The braking system also has a sensitive braking moment possibility to accurately control the running speed of the elevator near the traffic point.

The control modes of the mine hoist are manual, semi-automatic and fully automatic.

With the mining depth and the use of centralized lifting mode, the multi-rope friction mine hoist has an increased development prospect. The friction winding mine hoist of new structure has been used in some countries, which is important for deep well mining with lifting height.

Use and scope of application of the product

Multi-rope friction elevator is divided into well tower type and floor type according to the installation form, which is mainly used for coal, metal mines and non-metallic mines for lifting coal, minerals, lifting personnel, lowering materials and equipment.

The supporting electrical equipment of this product is non-explosion-proof type, so it can not be used in gas, coal dust and other flammable and explosive media places.

Execution standards for the product

Multi-rope friction hoist (JKWD, JKM) series products implement A01036-2007 “Safety inspection specification of multi-rope friction hoist for coal mine”, GB / T10599-2010 “multi-rope friction hoist” and 0 / HBSHM006-2010 “Enterprise standard” and other standards and ” coal mine safety regulations design and manufacturing.

Operational principle

The multi-rope friction elevator adopts the principle of flexible body friction transmission. The steel wire is built on the friction wheel, and the friction between the steel wire and the friction pad can realize the container lifting and lower heavy objects or personnel.

When the closed wire rope with the container drives the coil, the friction between the steel rope and the coil can realize the speed adjustment through electric transmission: the disc brake realizes the braking through hydraulic and electrical control: the container depth indication through various position indication system; the machine, electric and liquid combination system of various sensors and control components to monitor and protect the whole machine; and realize the information transmission inside and outside of the elevator through computer and network technology.

Advantages of a multi-rope friction hoist

(1) lifting container and load borne by more than wire rope, compared with the single rope winding lifting equipment, improve copper wire rope diameter is smaller, leading wheel diameter and the whole machine size are reduced, equipment quality is light, adapt to the large equipment, can meet the mine increasingly to the development of the deep deep demand.

(2) Because the lifting container is suspended on multiple wire ropes at the same time, these wire ropes will generally do not pull at the same time (the tension is too large when the wire rope will skid phenomenon), so it can not be set up.

(3) The multi-rope friction lifting system is generally a balance lifting system, and the dominant wheel diameter is small, the inertia and torque of the system are small, and the power and power consumption of the motor are small.

(4) The root number of the lifting wire rope is generally even, and the left and right twist is half, which can offset the loose twist torque in the operation of the wire rope, reduce the running resistance of the lifting container to the tank, and prolong the service life of the tank and the tank ear.

(5) When the tower lift is adopted, the friction wheel elevator is installed on the well tower, reducing the floor area of the elevator.

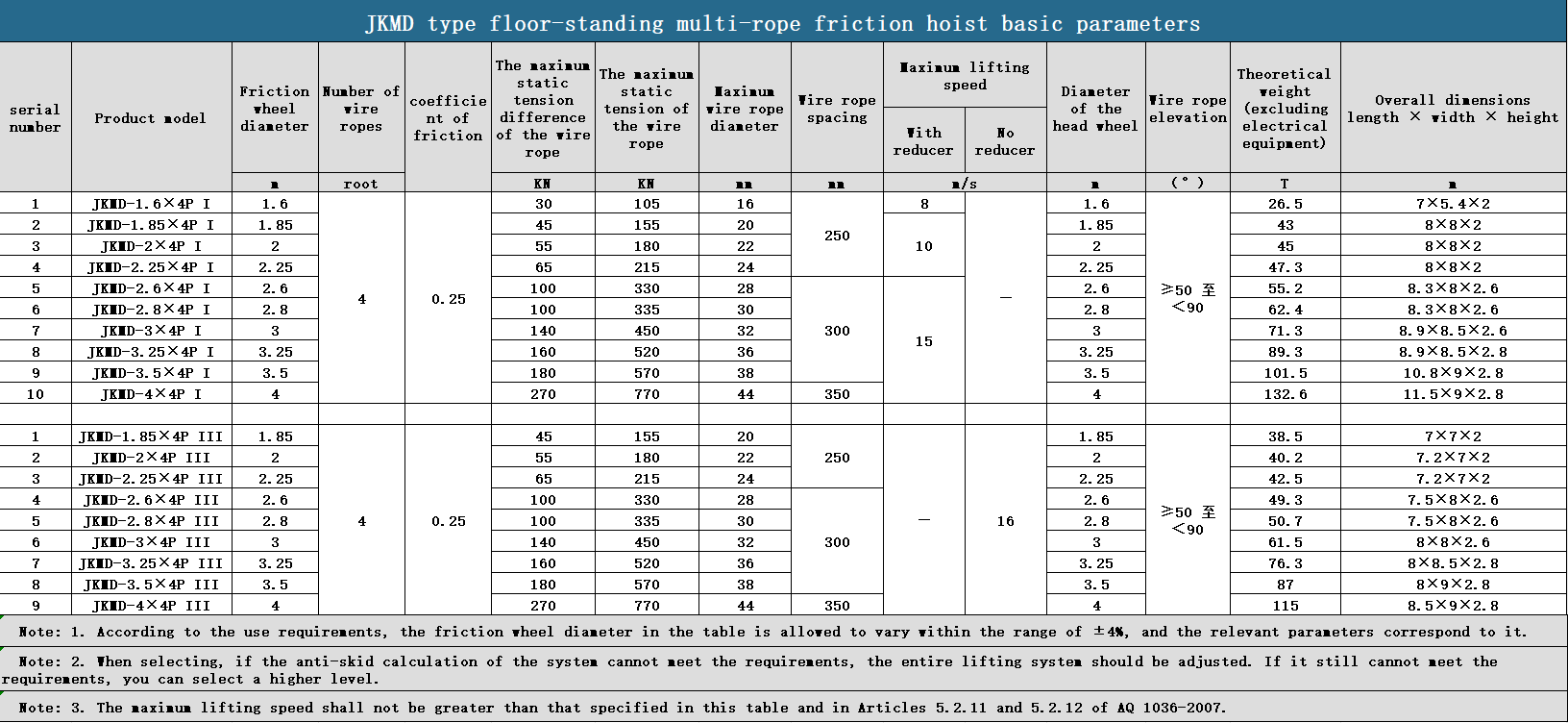

This data is for reference only and can be customized

CASE

Quality wins the market Trust creates the brand