JZP Series Shaft Drilling Winch

CATEGORIES

Send Message

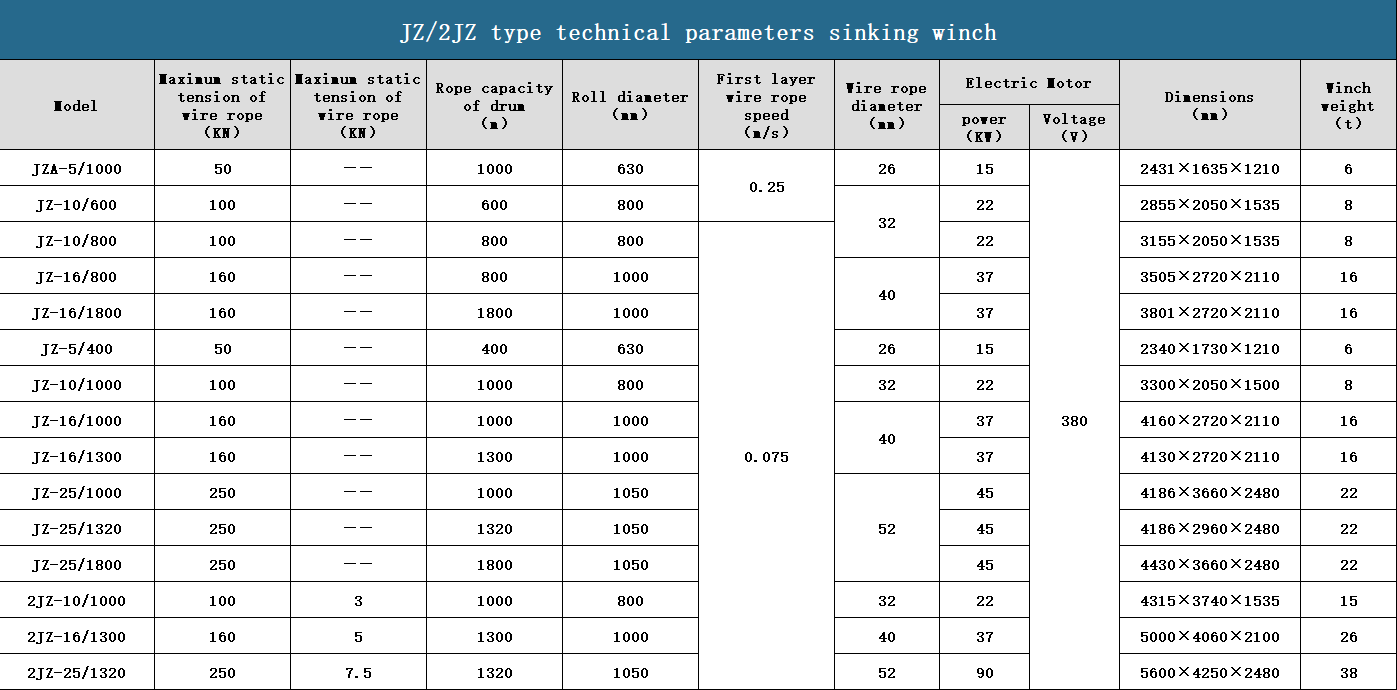

Product: JZP Series Shaft Drilling Winch

Introduce

The shaft-sinking winch is mainly used for suspension of hanging plates, water pumps, water pipes, grouting pumps, ducts and other tunneling equipment and tensioning ropes during the shaft excavation of coal mines, metal mines and non-metallic mines. Put the differential handle on the reducer in the differential position, and if the stable rope is tightened, the tension force of the two stable ropes can be kept equal; If the suspended water pipe, grouting pipe, hair dryer and other pipe equipment is kept perpendicular to the ground.

Technical feature

Strong lifting capacity large rope capacity smooth operation

Operational principle

The spindle device is composed of drum, shaft, bearings, large gears, brake wheels and other parts, and is the wire rope winding mechanism of the winch. The drum, gear, and brake wheel are tightly matched with steel sleeves and bolts to form an integral whole; The steel wire rope is fixed to the spoke of the brake wheel through the hole on the brake wheel using a pressure plate; The steel wire rope is pulled out above the drum.

The reducer is a gear spherical worm gear pair reducer, which has the characteristics of large load-bearing capacity, small volume, and high efficiency. Changing the position of the variable speed handle can enable the winch to achieve two speeds. During assembly, the relative position should be strictly controlled, and corresponding adjustment pads can be added or subtracted to achieve this.

The working brake adopts an electric hydraulic brake, and its working process is: when powered on, the hydraulic push rod rises and releases the brake; When power is cut off: the hydraulic push rod descends and brakes; During maintenance and installation,

It should be noted that the hydraulic push rod has a compensating stroke,

The safety brake adopts a belt brake, and when stopping, it relies on a heavy hammer to fall for braking; When starting up, the hydraulic thruster lifts the heavy hammer to release the brake,

The frame is welded with steel plates and profiles, divided into two parts: the main frame and the rotating frame. The connection is made with tapered pins and bolts, which is convenient for transportation and installation, and has no special requirements for the foundation.

CASE

Quality wins the market Trust creates the brand