Permanent Magnet Multi Rope Friction Hoisting Winch

CATEGORIES

Send Message

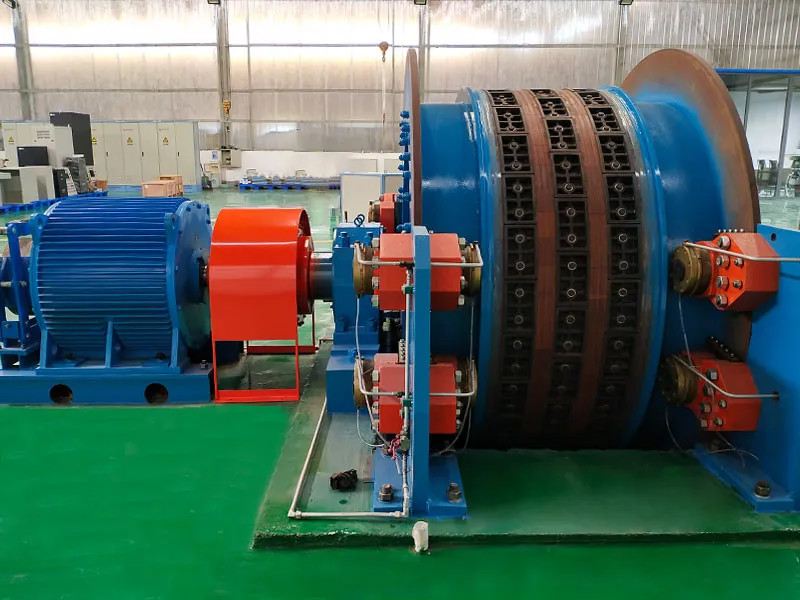

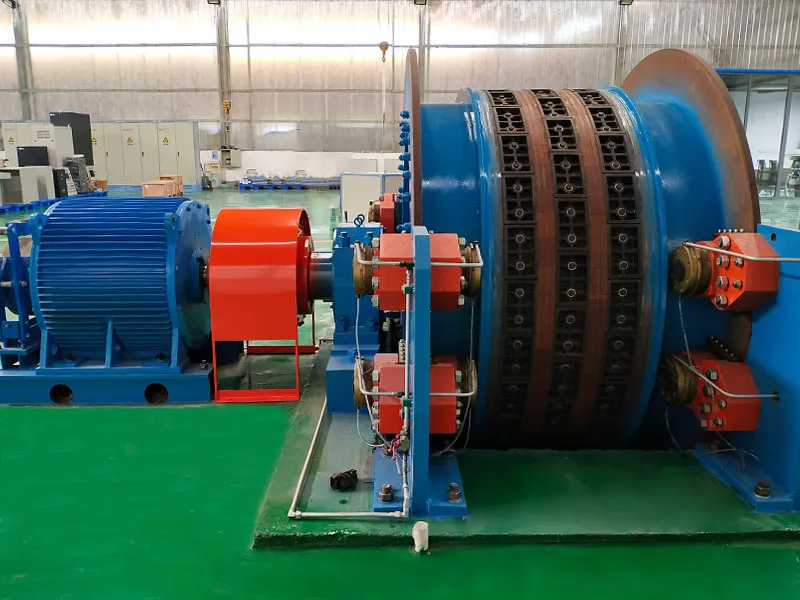

Product: Permanent Magnet Multi Rope Friction Hoisting Winch

Introduce

Permanent magnet multi rope friction hoist is mainly used for coal, metal mines and non-metallic mines for lifting coal, minerals, lifting personnel, lowering materials and equipment.

The supporting electrical equipment of this product is non-explosion-proof type, so it can not be used in gas, coal dust and other flammable and explosive media places.

Compared with traditional mining hoisting winches it has six advantages

Advanced Technology

The new generation of permanent magnet synchronous speed regulation technology has a speed regulation range of 0.01Hz~15Hz, which is 100 times more accurate than traditional hoist speed regulation, making the mining hoist winch run more smoothly.

Safe And Reliable

When the system loses power and the brake fails, the hoist can automatically enter the power generation state to generate electric energy to slow down the mining hoist winch, basically eliminating the occurrence of overspeed accidents.

Small Size And Light Weight

The permanent magnet built-in mining hoisting winch eliminates the reducer. The coupling, lubrication station, and motor are installed in the drum. The weight of the main machine is reduced by 45%, and the floor space is reduced by 50%. Equipment transportation and installation are more convenient, and infrastructure investment is significantly reduced.

Energy Saving

The permanent magnet built-in mining hoisting winch eliminates the power loss of reducers, couplings and lubrication stations, and improves work efficiency by 15%. In addition, it can feed back to the power grid under any load reduction working condition. Compared with traditional mining hoisting winches, The comprehensive energy saving can reach 30%.

Quiet And Low Noise

The noise of the permanent magnet built-in mining hoisting winch can be as low as 60dB, creating a quiet and comfortable operating environment in the machine room.

Low Maintenance

The permanent magnet motor technology is mature and the failure rate is extremely low. At the same time, there is no maintenance work on the reducer, coupling and lubrication station. The daily maintenance of the permanent magnet built-in mining hoisting winch is greatly reduced.

Installation, use and maintenance of mining hoisting winch (permanent magnet motor)

- It is strictly prohibited to open the cover while the power is on.

- During maintenance, pay attention to protecting the fasteners and the rubber sealing ring in the introduction device.

- When the equipment is running, it needs to be cooled by water. Cooling water: The cooling water temperature at the inlet of the motor should not be higher than +33°C, nor should it be lower than +5°C;The pressure of cooling water is 0.2~0.5MPa, and the flow rate is not less than 3t/h;

- The thermal protection element Pt100 is embedded in each phase at the end of the stator winding. The winding temperature shall not be higher than 130°C. Temperature protection and early warning are realized through the frequency converter. When the winding temperature reaches 120℃, the frequency converter should alarm, and when it exceeds 130℃, the frequency converter will automatically stop.

Notice:

- a) The maintenance of permanent magnet motors during use should be checked regularly according to coal mine safety regulations, such as the integrity of the outer surface, whether there is rust, etc.;

- b) Every week or so, use clean cotton or foam plastic to remove coal dust on the joint surface and apply anti-rust oil. Not too much anti-rust oil, otherwise it will affect the performance;

- c) Check whether the wiring is broken or loose;

- d) When the permanent magnet motor is used again after being idle for a long time, be sure to check whether its performance is intact.

- e) If any problem is found, it should be replaced and brought to the ground for repair.

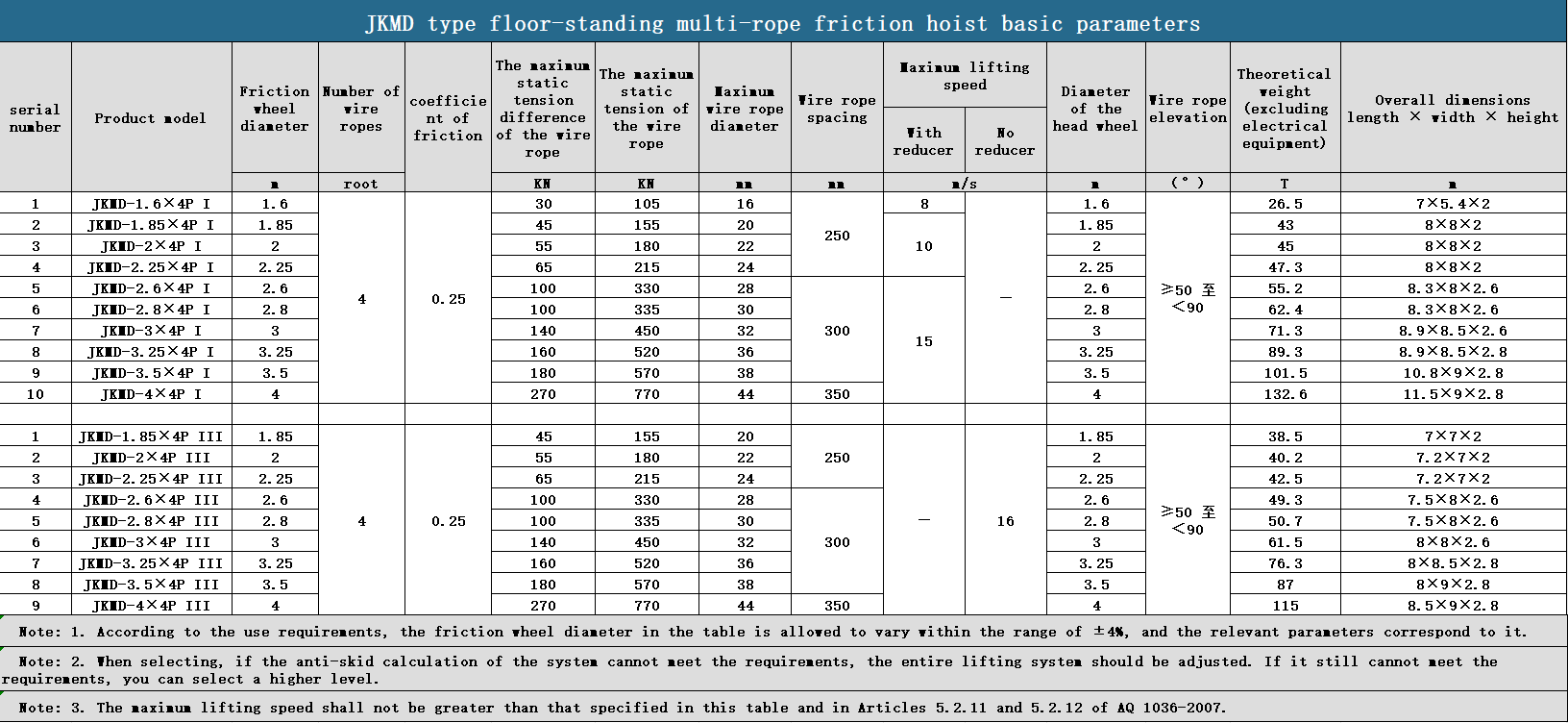

This data is for reference only and can be customized

CASE

Quality wins the market Trust creates the brand